|

Eastman Kodak

|

Stereolithography satisfies Kodak's goals of shorter lead times by reducing mold-making

times as much as 85% over traditional machining techniques for cost-effective low-volume production.

"Stereolithography has reduced the costs of our medium-volume manufacturing practices as much as 75% over traditional machining techniques."

- Joseph De Guglielmo, Technologist

Rapid Prototyping Advanced Machining Center

Eastman Kodak Co.

|

|

The Challenge

The Rapid Prototyping Center and the Plastics Model Shop at Eastman Kodak needed to develop the shortest possible lead times for low-volume production of plastic-injection-molded parts. The Model Shop, an in-house prototyping facility, manufactures prototypes, tooling and custom parts for Kodak product groups. Traditional machining of hard tooling was too costly and time consuming. Because of Kodak's experience with casting and prototyping with stereolithography, engineers decided to focus on the secondary tool approach afforded with SE and cast epoxy molds.

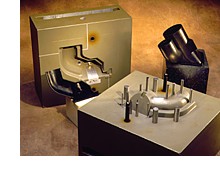

Building a suitable casting master using SL proved challenging. The cast epoxy molding process, which incorporates aluminum-filled epoxy material, exposes the master to extreme temperatures. Masters had to be durable and stable. Furthermore, the SL resin had to have minimal exothermic reaction with the epoxy casting materials. Finally, working parameters and design of the SL master would have to compensate for shrinkage and fit up between the SL resin and epoxy material.

The Results

A number of tests assured Kodak the SL process delivered accurate, durable and chemically and thermally stable casting masters. After toolmaking experts refined CAD files for parting lines, design conflicts, drafting angles and undercut, the SL process successfully produced masters used for casting molds.

A sample project required 25 different injection-molded plastic parts. Some of those cast epoxy molds have produced in excess of 2,000 production parts. Kodak expects total yields as high as 5,000 for parts having simple geometry, and 3,000 parts with complex geometries.

Additional benefits Eastman Kodak has gained include:

- 85% shorter lead times to produce complex plastic-injection molded parts

- Product development cycles that have been cut by 1 year

- Mold-making costs at 75% of traditional machining methods

- Fast proofing of design iterations

- Quickly evaluating form and fit of production parts

The Process

The Rapid Prototyping Center and the Plastics Model Shop work from solid-model CAD files created by Kodak product-development groups. An experienced toolmaker, called a computer-aided toolmaker (CAT), reviews and refines the file. CATs check the CAD file for proper orientation, parting lines, shrinkage and fit up, drafting angles and undercuts.

The CAT and the SL technician work together to identify the right combination of SL resin, epoxy material and epoxy casting methods that produces minimal exothermic interaction between the SL resin and the epoxy material. Additional design modifications now address differences in thermal expansion and contraction between the resin and the cast epoxy material.

The SLA creates master part models that undergo finishing. Cast molds of aluminum-filled epoxy are molded from the masters. These cast molds then mount in an injection-molding machine.

Over 40 epoxy-constructed molds have been built thus far at Kodak. Some epoxy molds have adequately injection-molded over 2,000 parts and are expected to create up to 5,000 molded parts.

This approach affords the Rapid Prototyping Center and Plastics Model Shop delivery of simple molds for low-volume production in 2-4 weeks, where once it required 8-10 weeks. The center now delivers complex molds in 6 weeks, an 85% reduction in delivery times over the 6-9 months required with conventional mold-making processes.

The Tools

- SLA 250 with Cibatool SL 5170 resin

- SLA 350 with Cibatool SL 5190 resin

- SLA 500 with Cibatool SL 5180 resin

Company Profile

Eastman Kodak Company serves the imaging needs of consumers and commercial customers worldwide with a wide variety of chemical imaging products, including films, papers, chemicals and equipment and digital products including cameras and processors that employ unique Kodak technology.

|