|

Molex

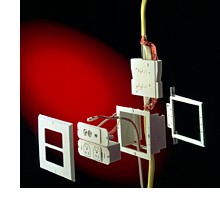

Molex launches 20 new SMART HOUSE system products in under 11 months

using stereolithography, showcasing its new product line roll-out at the

National Association of Home Builders annual trade show.

Molex launches 20 new SMART HOUSE system products in under 11 months

using stereolithography, showcasing its new product line roll-out at the

National Association of Home Builders annual trade show.

"With the SLA, we can do 2-1/2 man-years of work in 4-1/2 months."

- Robert Olson, Model Shop Supervisor, Molex

The Challenge

From more than 50 proposed products designed for Molex's new SMART HOUSE premise wiring system, 20 new products were to be developed, tested and released. In only 11 months. Using only existing resources. The National Association of Home Builders' annual trade show and convention in Las Vegas, Nevada was only 11 months away, and meeting this deadline was critical to seizing a prime market opportunity at the major builder event of the year. Having the products ready on time also represented a significant financial commitment, and once the commitment was made, credibility was on the line.

SMART HOUSE represented an exciting new market for Molex, with products that are used by consumers rather than original equipment manufacturers. Aesthetics of the finished parts were important, since the end-use is in fine homes.

The Results

Using stereolithography, all 20 products were developed, tested, finished, tooled and in production in only 10 months at a dollar savings of at least 70%, and a time savings of at least 40%.

Many problems encountered in the design analysis were solved with the help of the SLA. For example, one part was built four times the actual size so mold designers could evaluate the design prior to mold tooling. Another part was made at reduced size for easier installation. Another part was quickly redesigned after a UL review identified potential heat dissipation problems.

Other benefits Molex realized were the abilities to:

- Quickly modify and produce complex parts to enable multiple revisions for evaluating

- Evaluate production form and fit to produce quality multiple-piece prototypes

- Evaluate finely detailed, end-quality prototypes for aesthetic considerations

- Identify potential problems prior to tooling

- Easily change size of part if design is too big or too small

- Assist mold designers in designing and producing molds

- Quickly evaluate, adjust, and retest assembly tooling

- Photograph finished SLA prototype parts for brochures and ads months before manufacturing begins

Before SL, Molex would not have been able to produce core models for many of the proposed products. Since a reliable core model is essential to the production of many of the more complex designs, these products would not have been developed.

The Process

Molex started with 50 CAD solid models developed in Intergraph's Microstation Software. Many of the parts were eliminated from consideration after the CAD drawings were analyzed. The design data for the remaining parts were processed and the pants were built on their SLA 250.

The 20 stereolithography prototypes proved essential in meeting the 11-month deadline. SL parts were used in virtually every aspect of SMART HOUSE product line development, from form and fit testing to mold design to marketing. For example, the SL model of a Dimmer Sensor Block, comprising multiple components, helped Molex identify a problem with the part's aesthetics, and discover that a reduction in size was needed to ensure a secure fit.

In developing a Wire Trap Connector, the SL model allowed them to quickly evaluate assembly tooling, make the necessary adjustments and recheck the changes. In fact, SL models, finished to mirror the final products, were photographed and used to develop SMART HOUSE brochures and advertising while the products were still under development. The promotional materials were ready for simultaneous release with the SMART HOUSE premise wiring system.

The Tools

- Intergraph Microstation Software

- SLA 250

Company Profile

For over 50 years, Molex has made connectors, cables, and interconnection systems for a wide variety of products such as telephones, TVs, VCRs, PCs, appliances, and security systems. More recently, Molex has teamed up with SMART HOUSE to produce signal and power distribution systems which provide the homeowner with flexible communication and power control from within the home, car or office.

|